Komatsu PC240 Used Excavator 2019 hot Sale

Key Product Advantages

1. Superior Fuel Efficiency

Equipped with Komatsu’s advanced CLSS (Closed Center Load Sensing System) hydraulic system, the PC240 optimizes fuel consumption while maintaining high productivity. Its Eco-Gauge mode further reduces fuel usage by automatically adjusting engine and hydraulic power to match workload demands.

2. Enhanced Operator Comfort

The ergonomically designed cab features a spacious, vibration-damped environment with intuitive controls, adjustable seats, and excellent visibility. The 7-inch LCD monitor provides real-time machine data, ensuring operators work efficiently and comfortably during long shifts.

3. Outstanding Durability & Reliability

Built with Komatsu’s robust components and reinforced structures, the PC240 excels in tough conditions. Critical parts, such as the undercarriage and boom, are engineered for extended service life, minimizing downtime and repair costs.

4. Advanced Technology Integration

Smart Construction Compatibility: Supports Komatsu’s 3D machine control systems (optional) for precise grading and excavation.

KOMTRAX Remote Monitoring: Tracks machine location, fuel levels, maintenance schedules, and performance metrics in real time via telematics.

5. Environmentally Compliant

The PC240 meets stringent global emissions standards (e.g., EU Stage V, U.S. Tier 4 Final) thanks to its clean-engine technology, including a Diesel Particulate Filter (DPF) and optimized combustion system.6. Versatile Performance

Adaptable to diverse applications (digging, trenching, loading, etc.) with multiple attachment options (grapples, breakers, etc.). Its 17.5-ton class balance of power and agility makes it ideal for urban construction and medium-scale projects.7. Safety-First Design

Features include 360° camera systems (optional), anti-slip platforms, and ROPS/FOPS-certified cabins to protect operators in hazardous environments.8. Easy Maintenance

Centralized grease points, ground-level service checks, and extended filter intervals reduce maintenance time. The auto-shutdown greaser ensures critical components are lubricated, enhancing longevity.9. Cost-Effective Operation

Low fuel consumption, minimal downtime, and long component lifecycles translate to reduced total ownership costs (TCO). Komatsu’s global support network guarantees prompt parts availability and technical assistance.

The Komatsu PC240 combines cutting-edge technology, operator-centric design, and rugged reliability to deliver unmatched efficiency and value for mid-sized excavation projects. Its eco-friendly performance and adaptability make it a top choice for contractors prioritizing productivity and sustainability.

main features of the Komatsu PC240 Excavator:

Powerful Engine

Equipped with a high-performance Komatsu SAA6D107E-3 engine, delivering robust power output (approx. 138 kW/185 hp) while maintaining fuel efficiency and low emissions.Operating Weight & Class

A medium-sized hydraulic excavator with an operating weight of approximately 24,700–26,100 kg (depending on configuration), suitable for a wide range of construction, mining, and earthmoving tasks.Advanced Hydraulic System

Features Komatsu’s CLSS (Closed Center Load Sensing Hydraulic System) for smooth, responsive control, optimized digging force, and improved fuel efficiency.High Digging Performance

Offers exceptional digging force (up to 178 kN bucket force) and lifting capacity, ensuring productivity in tough conditions.Operator Comfort & Safety

Spacious, ergonomic cab with adjustable seating, intuitive controls, and reduced noise/vibration.

Advanced monitoring system with a LCD display for real-time diagnostics and machine status.

ROPS/FOPS-certified structure for operator protection.

Durable Construction

Reinforced undercarriage, heavy-duty boom/arm, and abrasion-resistant components ensure longevity in demanding environments.

Eco-Friendly Design

Complies with stringent emission standards (e.g., Tier 4 Final/EU Stage V) via advanced engine technology and exhaust treatment systems.

Versatility

Compatible with numerous attachments (e.g., buckets, breakers, grapples) for diverse applications like digging, grading, demolition, and material handling.

Easy Maintenance

Centralized service points, extended filter life, and ground-level access to key components simplify routine maintenance.

Intelligent Machine Control (Optional)

Available KOMTRAX telematics system enables remote monitoring of location, fuel usage, and machine health for fleet management optimization.

Construction & Earthmoving

Building foundations: Digging trenches, leveling sites, and preparing ground for residential or commercial structures.

Mass excavation: Moving large volumes of soil, gravel, or debris in infrastructure projects.

Road & Highway Construction

Road grading: Shaping roadbeds and slopes.

Ditch digging: Creating drainage systems or utility trenches.

Laying pipes/conduits: Precise trenching for underground utilities.

Mining & Quarrying

Material handling: Loading trucks with aggregates, coal, or ore in small to medium-scale mining operations.

Stockpiling: Organizing extracted materials.

Landscaping & Site Development

Park/golf course construction: Shaping terrain, ponds, or decorative features.

Vegetation clearing: Using thumb attachments to remove roots, rocks, or trees.

Demolition

Building teardowns: Equipped with hydraulic breakers or shears for controlled demolition of structures.

Agriculture & Forestry

Farmland preparation: Digging irrigation channels or ponds.

Log handling: Using grapples to move timber or clear land.

Utility Work

Telecom/water/gas line installation: Precision digging in urban or rural areas.

Cable laying: Trenching for electrical or fiber-optic networks.

Disaster Relief

Debris removal: Clearing rubble, fallen trees, or flood-damaged materials.

Infrastructure Projects

Bridge/railway construction: Excavating abutments or embankments.

Dam/levee maintenance: Repairing or reinforcing earth structures.

Material Recycling

Waste sorting/handling: Using sorting grapples in recycling facilities.

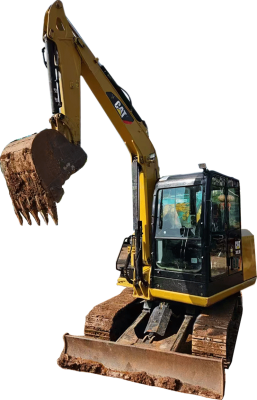

Technical parameters (partial)

Operating Weight: Approximately 24,000 kg

Bucket Capacity: 1.0–1.2 cubic meters

Maximum Digging Depth: Around 7.2 meters

Engine Power: Approximately 127 kW (170 hp)

Transport Length: Approximately 9.5 meters

Transport Width: Around 2.8 meters

Transport Height: About 3.0 meters

Packaging & Shipping

FAQ