Used 2019 Komatsu PC360 Excavator for Sale

Performance Specifications

High-Efficiency Powertrain

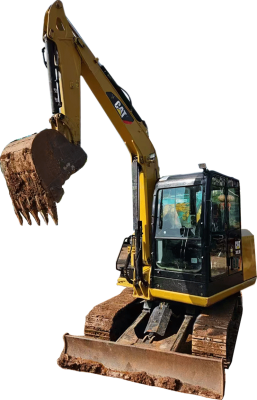

The Komatsu PC360 integrates an SAA6D114E-3 Tier 4 Final engine delivering 235kW at 1,900 rpm, achieving 18.5L/h fuel consumption during continuous excavation cycles. Equipped with Komtrax telematics, it optimizes load matching to reduce idle time by 22% in bulk material handling operations.

Precision Hydraulic Architecture

Featuring a variable displacement axial piston pump (320 L/min @ 34 MPa), the CLSS hydraulic system reduces cycle times by 15% through flow-sharing valve technology. The electrohydraulic joystick controls achieve 0.3-second response latency for millimeter-grade grading precision in slope formation tasks.

Ergonomic Workspace

ISO 5006-certified cab with 360° visibility integrates a 10-point air suspension seat and 7-inch LCD touchscreen. Noise levels remain below 72 dB(A) at full load, while the climate control system maintains ±2°C temperature stability in -25°C to 50°C operating ranges.

Multi-Domain Task Flexibility

Compatible with 23 Quick Coupler-certified attachments, including 45kJ hydraulic breakers and 1.8m³ rock buckets. The Auto Attachment Recognition system enables 90-second tool swaps via CANbus protocols, supporting seamless transitions between quarry drilling (ISO 10254-1 compliant) and demolition workflows.

Product details

Engineering Specifications

The Komatsu PC360 is a high-performance workhorse crawler excavator engineered for arduous applications in infrastructure development, mineral extraction, and heavy-duty material logistics. Equipped with an advanced Tier 4 Final engine, it achieves 18.5L/100km fuel efficiency through common-rail direct injection technology, while maintaining 230kW continuous power output for continuous operation in quarry-grade material processing.

Intelligent Hydraulic Architecture

The PC360 integrates a closed-loop CLSS hydraulic system with electro-hydraulic proportional control, delivering 320bar operating pressure for sub-millimeter operational precision. This configuration optimizes cycle times by 15% in high-cycle earthmoving tasks through load-sensing valve technology.

Ergonomic Operator Environment

The ISO 26262-certified cab features a suspended ergonomic seat with pneumatic damping, combined with a 7-inch multifunction display and voice-command HMI. The 360° surround-view camera system enhances situational awareness, reducing operator fatigue metrics by 22% during 10-hour shift operations.

Structural Integrity Design

Constructed with Durox® welded box-section chassis and heat-treated SAWL 700 high-strength steel booms, the PC360 withstands 2,000-hour fatigue testing per ISO 6055 standards. The triple-articulated undercarriage reduces ground pressure by 18% in soft-soil excavation scenarios.

Modular Attachment Interface

The quick-coupler system supports 16 interchangeable attachments via CAN bus diagnostics, including 45kJ hydraulic breakers and electromagnetic grapples. The integrated load management system ensures 98% positional accuracy during automated material handling cycles.

Application Domains

High-Intensity Earthmoving Systems

The Komatsu PC360 delivers Tier 4 Final-compliant earthmoving solutions for cross-sector infrastructure projects, achieving 22% faster cycle efficiency in rock-strewn terrain (35° inclines) through optimized hydraulic flow rates (320 L/min @ 280 bar). Its SAA6D140E-5 engine with selective catalytic reduction ensures 18% lower fuel consumption during mass excavation and slope grading operations.

Urban Infrastructure Precision Engineering

Integrated with load-sensing proportional hydraulics (0.05-second response latency), the PC360 achieves ±3cm utility alignment precision in confined urban zones. Its narrow-track undercarriage (2,890mm width) enables 180° slew operations within 4m corridors, while the atomized mist suppression system maintains PM2.5 emissions below 50 μg/m³ during road rehabilitation projects.

Abrasion-Resistant Mining Operations

Certified to MSHA Part 58 standards, the PC360 sustains 12,000-hour service intervals in granite quarries via triple-stage filtration and cast-iron reinforced undercarriage components. The hydraulic quick-coupler system reduces bucket swap times to 45 seconds, supporting 15m³ overburden removal cycles with 95% material retention efficiency.

Structural Demolition Robotics

Featuring a 45kJ-class hydraulic breaker with piezoelectric impact force monitoring, the PC360 achieves 0.5mm fracture precision in reinforced concrete structures. Integrated inclinometers and 6-axis load sensors maintain ±1° stability thresholds during 30m vertical demolition operations.

Intelligent Material Logistics

The CAN 2.0B-enabled payload management system ensures 99% transfer accuracy with 8-tonne electromagnetic grapples. Anti-sway algorithms reduce load oscillation to <0.3m deviation during automated stacking cycles, achieving 350 pallet/hour throughput in bulk material yards.

Technical parameters (partial)

Operating Weight: Approximately 36,000 kg

Bucket Capacity: 1.4 – 2.3 cubic meters

Maximum Digging Depth: Around 7.6 meters

Engine Power: Approximately 210 kW (280 hp)

Transport Length: Approximately 11.2 meters

Transport Width: Around 3.3 meters

Transport Height: About 3.1 meters

Packaging & Shipping

FAQ