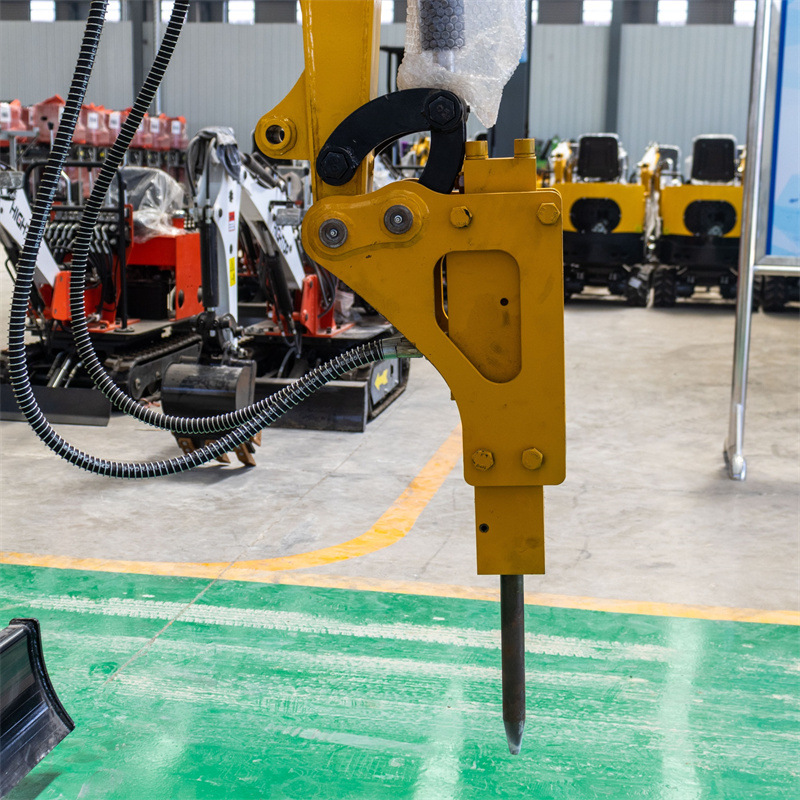

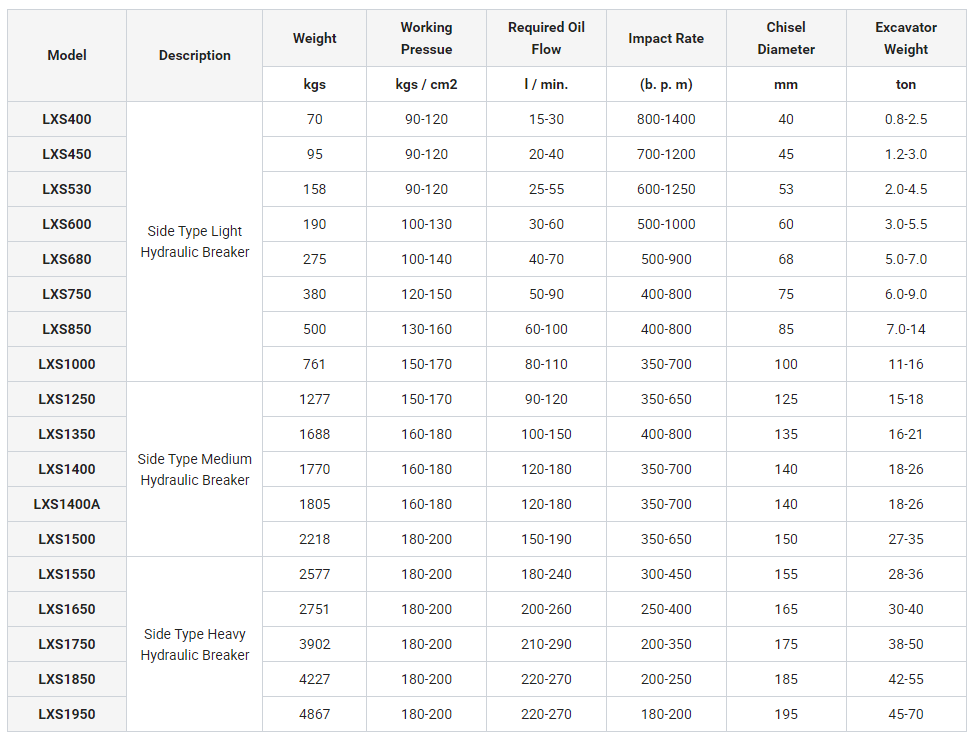

LXS850 Side Type Hydraulic Concrete Breaker Rock Hammer

Advantages of Hydraulic Breaker

LAOXIAO Hydraulic Breakers

Precision Power for Demanding Environments

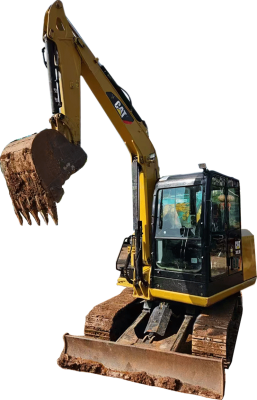

Engineered to deliver industrial-grade impact for concrete demolition, rock fracturing, and pile-driving operations, LAOXO hydraulic breakers feature proprietary vibration-dampening technology that reduces equipment stress by 62% while extending service life. Universally compatible with 30+ global machinery brands, including Kubota, Bobcat, CAT, John Deere, Volvo, and XCMG.

Engineering Breakthroughs

Why LAOXIAO Dominates

✅ Smart Impact Control – Adaptive hydraulics auto-adjust for concrete vs. bedrock

✅ Rebar-Shearing Force – 1,800 Joules impact energy cracks reinforced foundations

✅ Arctic-Ready Design – Operates at -30°C without performance loss

✅ Noise-Optimized – 85 dB max output for urban compliance

✅ Quick-Connect System – <2-minute tool-free attachment

Technical Superiority

Operational Lifespan: 8,000+ hours (3× industry average)

Pressure Optimization: Patented ECO-Hydraulics™ reduces pump wear

Material Versatility: Processes granite (6.5+ Mohs), asphalt, and steel-composite surfaces

Applications of Side-Type Hydraulic Breakers

Mining & Quarrying

• Ore extraction in hard rock formations

• Secondary rock fragmentation at processing sites

• Tunneling through granite, basalt, and metamorphic strata

Demolition Engineering

• Precision concrete structure dismantling (walls, slabs, foundations)

• Rebar-infused concrete separation in high-rise deconstruction

• Industrial plant teardowns with material segregation

Civil Infrastructure

• Roadway rehabilitation (asphalt/concrete pavement fracture)

• Bridge abutment removal and railway track bed preparation

• Trenching for underground utilities (gas/water pipelines)

Metallurgical Operations

• Furnace lining removal in steel plants

• Slag processing and ladle cleaning

• Scrap metal preparation for recycling

Arctic & Cold Climate Work

• Port icebreaking for maritime operations

• Permafrost excavation in pipeline construction

• Frozen material processing (-40°C rated operations)

Urban Development

• Brownfield site preparation with contaminated concrete removal

• Subway tunnel excavation in congested urban zones

• Historical building retrofitting with vibration-controlled demolition

Agricultural Applications

• Boulder clearance for land reclamation

• Irrigation channel excavation in rocky terrain

• Tree root system removal without topsoil disruption

Hydraulic System-Specific Tasks

• Pile driving preparation through compacted substrates

• Rock anchoring for slope stabilization projects

• Precision trench blasting in sensitive geological zones

Environmental Remediation

• Contaminated concrete slab fragmentation for safe disposal

• Demolition waste size reduction for recycling efficiency

• Riverbed dredging and flood control channel maintenance

Specialized Industrial Use

• Shipbreaking operations in dry dock facilities

• Foundry floor maintenance and ladle station cleanup

• Cement kiln refractory material removal

Technical Advantages in Application

• Processes materials up to 8.5 Mohs hardness

• Achieves 2,500-3,200 BPM impact frequency for rapid breakdown

• Maintains <85 dB noise levels for urban compliance

• Operates in -30°C to +50°C extreme temperatures

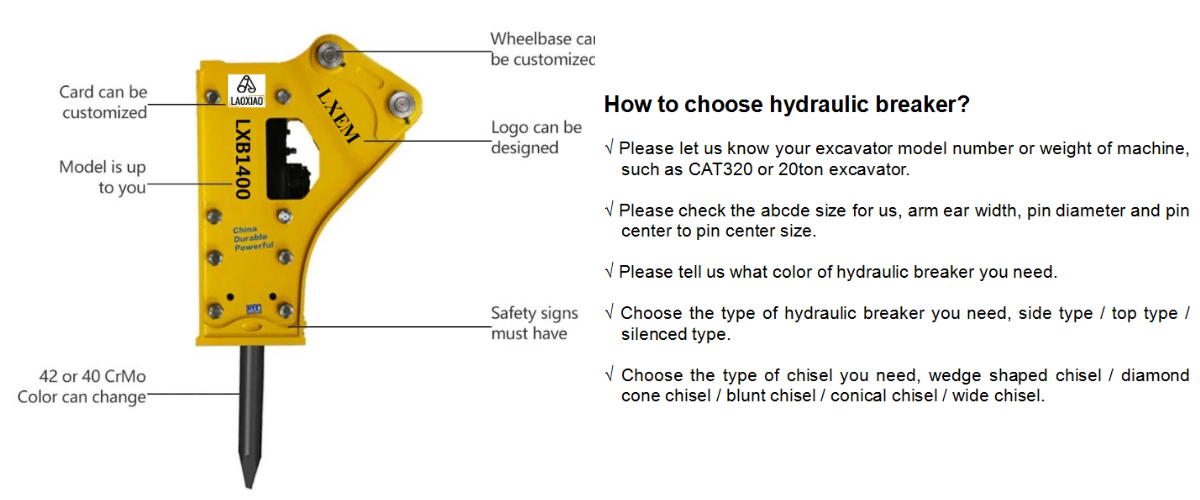

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery