Applications of LXEM Hydraulic Breakers

Structural Demolition: Efficiently dismantles reinforced concrete structures (C30–C80) and steel-reinforced slabs at 40–60 m²/h using adjustable multi-directional impact force (3,000–8,000 N).

Foundation Preparation: Cuts through 300–500 mm thick concrete foundations at 1.2 m³/h, integrated with ISO 14001-compliant dust suppression systems for environmentally sensitive sites.

Selective Demolition: Precision targeting allows removal of specific structural elements while preserving adjacent areas, ideal for urban renovation projects.

Rock Fragmentation: Processes igneous/sedimentary rocks (Mohs 6–7) at 8–12 tons/hour via high-frequency impact (1,200 BPM), achieving 95% material reduction efficiency.

Boulder Handling: Clears oversized boulders and clogs in primary crushing stations, enhancing quarry productivity and reducing operational costs.

Underground Mining: Operates on 35° slopes with anti-vibration mounts (≤2.5 m/s² r.m.s.), reducing equipment wear by 30% in confined spaces.

Asphalt Milling: Shatters 150–300 mm asphalt layers at 500 m²/day (ISO 11805-rated), with 95% RAP recycling integration for sustainable road maintenance.

Concrete Road Breaking: Recovers 85% aggregate for immediate reuse via controlled fragmentation (≤50 mm particle size), compliant with ASTM D5240 standards.

Railway & Tunnel Construction: Excavates mountainous terrain, drills tunnels, and stabilizes subgrades, supporting railway expansion projects.

Earthquake Debris Clearance: Deployed in confined spaces (≤1.2 m clearance) with 8-ton impact force to clear 50 m³/day rubble, featuring ATEX Zone 2 explosion-proof certification for hazardous environments.

Collapse Rescue Operations: Integrates with UAV positioning systems (±10 cm accuracy) for rapid debris removal in unstable structures, reducing rescue timelines by 40%.

Port & Marine Construction: Handles underwater rock fragmentation and concrete demolition in ports, including submerged reef removal and caisson dismantling.

Steel & Recycling: Processes recycled concrete and asphalt to extract reusable materials, supported by wear-resistant tungsten carbide tools (density ≥14.5 g/cm³).

Permafrost & Ice Handling: Breaks frozen ground and ice formations in polar regions, enabling infrastructure development in extreme climates.

Utility Infrastructure: Excavates subsurface utilities and demolishes urban concrete structures while minimizing vibration and noise for residential areas.

Historic District Renewal: Precision-controlled impact limits collateral damage during renovation of heritage buildings.

Landscaping: Clears compacted soil and rocks for park construction or slope stabilization.

Industrial Maintenance: Breaks up hardened slag and scale in steel mills and foundries, improving production line efficiency.

Waste Management: Processes construction debris and industrial waste into reusable aggregates, aligning with circular economy goals.

Oil & Gas: Supports pipeline installation by breaking through rocky terrains and frozen soils, with ATEX-certified models for explosive environments.

Renewable Energy: Clears land for solar farms and wind turbine foundations in challenging geological conditions.

LXEM Advantage:

The LXEM Hydraulic Breaker combines multi-material adaptability, rugged durability, and smart technology to excel in diverse sectors—from mining and demolition to emergency response and sustainable infrastructure. Its modular design, IoT-enabled diagnostics, and compliance with global standards (OSHA, EN, ATEX) ensure reliability across demanding applications.

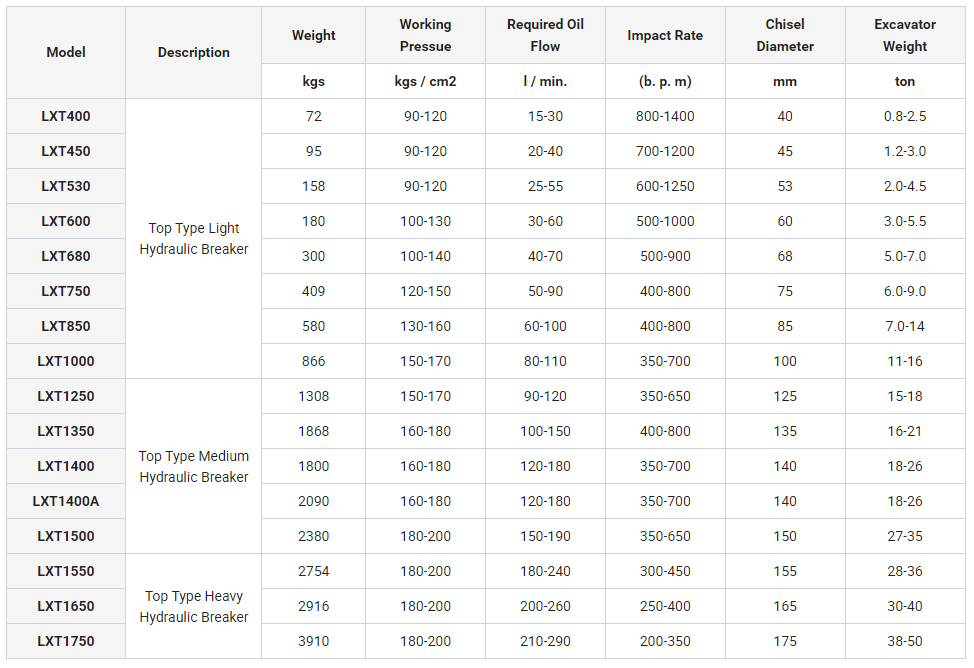

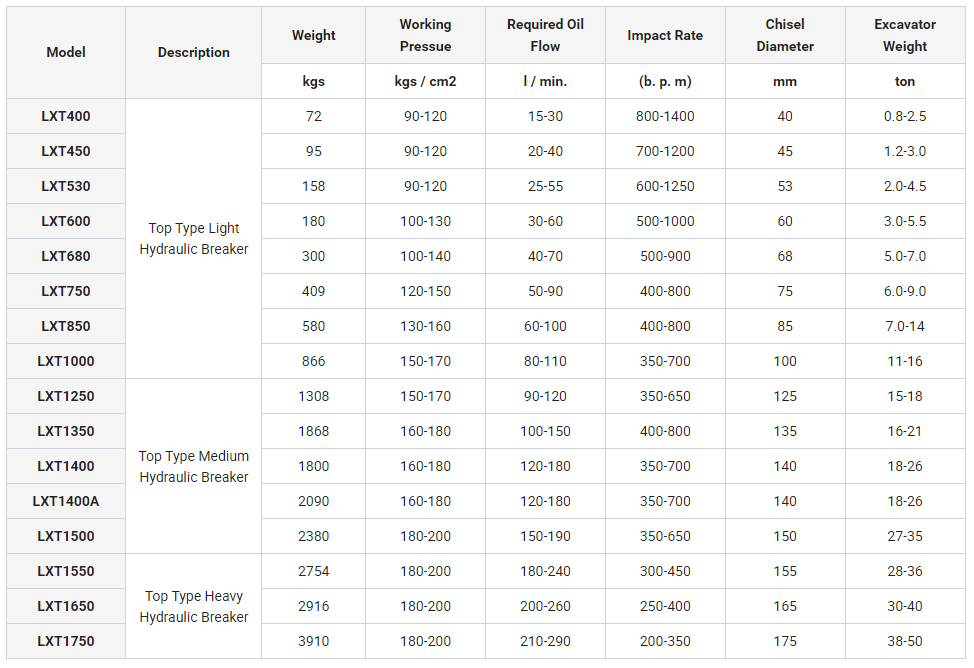

Technical Specifications

The data is for reference only, and the specific product data is subject to the actual product.

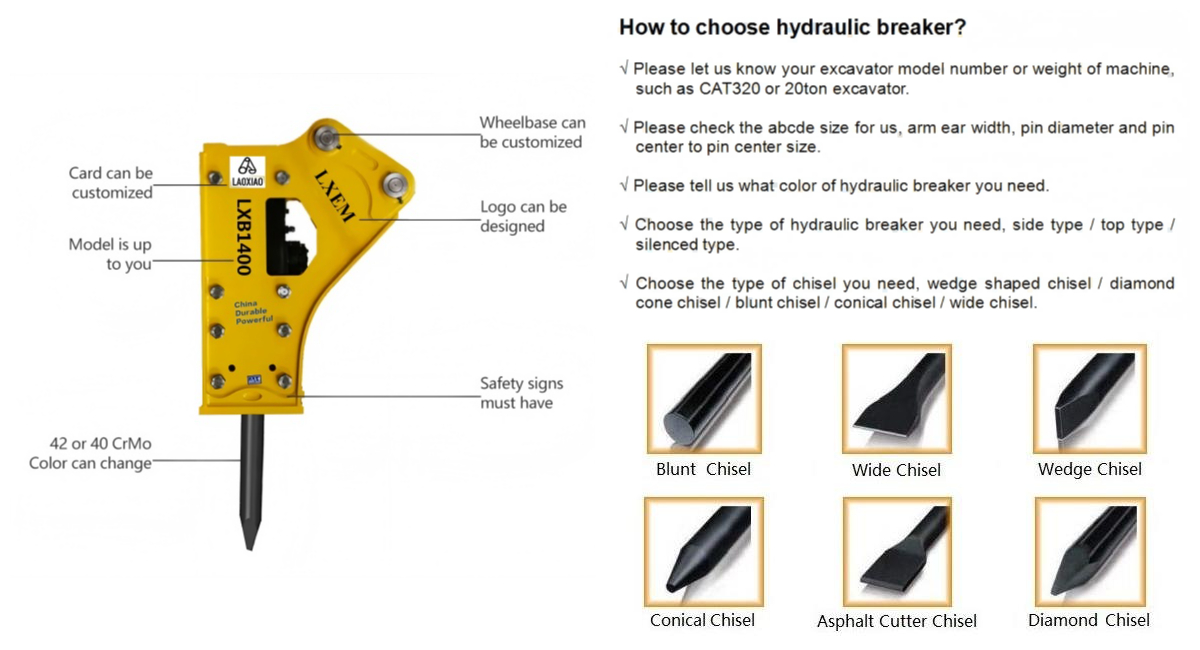

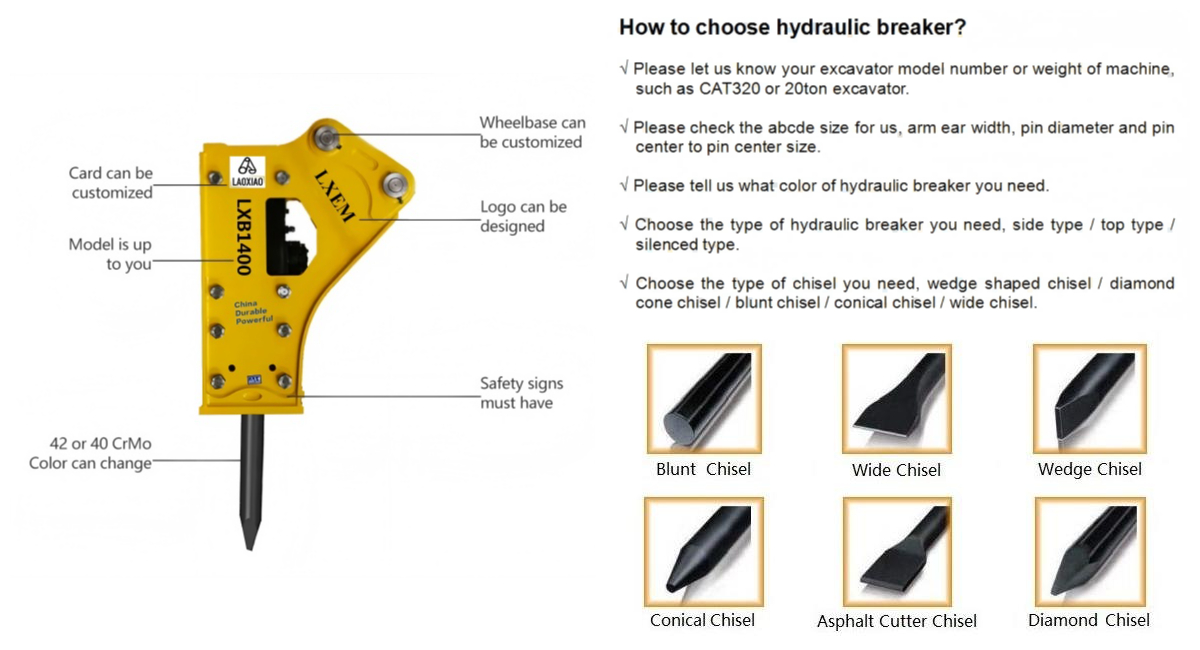

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery