LXT850 Top Type Hydraulic Concrete Breaker Rock Hammer

Key Advantages of LXEM Hydraulic Breakers

🔹 Factory-Direct Pricing

Competitive rates with no intermediaries, ensuring maximum cost-efficiency for bulk or single-unit orders.

🔹 Flexible Ordering Policy

MOQ of just 1 set – ideal for trial purchases, niche projects, or phased procurement.

🔹 Premium Quality Assurance

Precision-engineered components backed by a comprehensive 12-month warranty, guaranteeing reliability and reduced downtime.

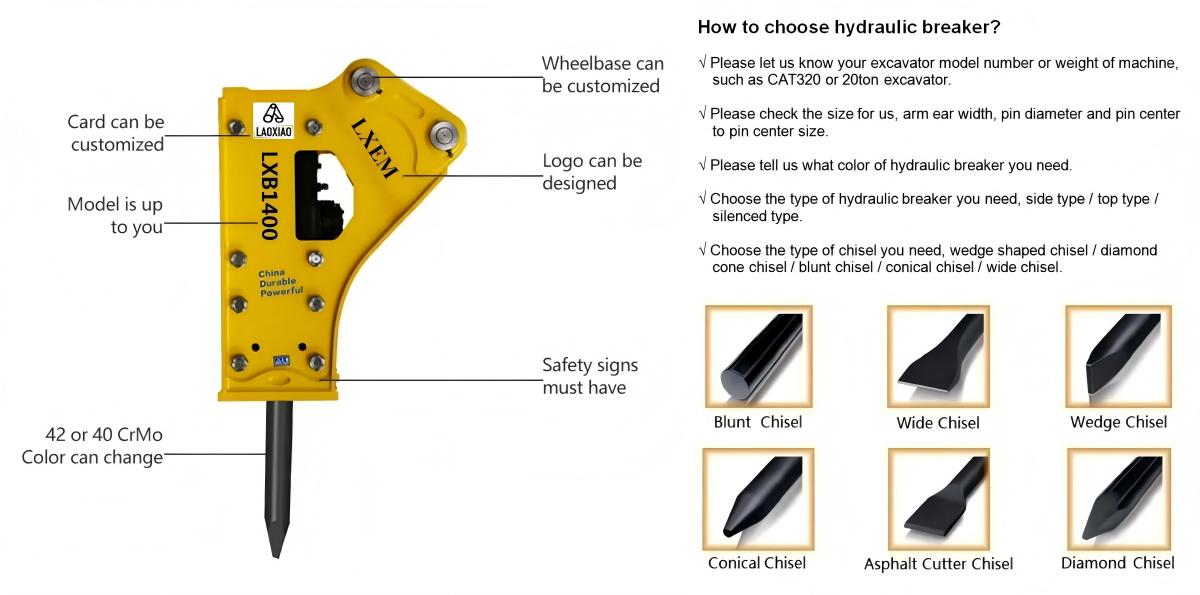

🔹 Versatile Chisel Specifications

Tool-steel chisels available in 35–210 mm diameters, covering applications from light-duty trenching to heavy-duty rock fragmentation.

Applications of LXEM Hydraulic Breakers

LXEM hydraulic breakers deliver precision, power, and versatility across diverse industries, leveraging advanced hydraulic technology for efficient material fragmentation and structural dismantling. Below is a detailed breakdown of their applications:

1. Mining & Quarrying

Surface Mining

- Primary Excavation: Breaking hard igneous/sedimentary rocks (Mohs 6–8) for open-pit mining operations, including overburden removal and bench blasting.

- Secondary Crushing: Reducing oversized boulders (1–3 m³) to transportable sizes at crushing stations, achieving 95% material reduction efficiency.

- Grizzly/Screen Station Operations: Clearing clogged material in screening plants to maintain continuous production flow.

- Slope Stabilization: Fragmenting unstable rock formations on 30°–45° slopes with anti-vibration technology (≤2.5 m/s²) to minimize equipment wear.

Underground Mining

- Drift & Stope Development: Excavating tunnels and stopes in narrow-vein mines, compatible with compact breaker models for restricted spaces.

- Muck Handling: Breaking up ore and waste rock in haulage drifts for efficient loading into transport vehicles.

2. Metallurgical & Industrial Operations

Steel & Foundry Work:

- Ladle Demolition: Removing spent refractory linings from steel ladles and torpedo cars.

- Slag Removal: Breaking up solidified slag from blast furnaces and refining units (up to 2 m thickness).

- Furnace Dismantling: Dismantling refractory structures in blast furnaces, reheating furnaces, and coke ovens.

- Heavy Equipment Foundations: Demolishing reinforced concrete bases (C30–C60 grade) for machinery, tanks, or industrial plants.

- Recycling Facilities: Fragmenting scrap metal, concrete, and asphalt for material recovery.

3. Construction & Demolition

Structural Demolition

- High-Rise Buildings: Precision dismantling of reinforced concrete columns, beams, and floors using adjustable impact force (3,000–8,000 N).

- Industrial Structures: Breaking down power plant structures, silos, and storage tanks.

- Bridge/Viaduct Removal: Demolishing concrete decks, piers, and abutments, with rebar-separation capabilities.

Foundation Work - Excavation: Cutting through 300–500 mm thick concrete slabs at 1.2 m³/hour for basement or utility installations.

- Pile Breaking: Removing concrete piles and caissons during site reconstruction.

Environmental Compliance: - Integrated dust suppression systems compliant with ISO 14001 for low-emission operations in urban areas.

4. Road & Rail Infrastructure

Road Maintenance

- Asphalt Recycling: Removing 150–300 mm thick asphalt layers (500 m²/day) for 95% reclaimed asphalt (RAP) reuse.

- Concrete Pavement Demolition: Breaking rigid pavements into ≤50 mm fragments (ASTM D5240 compliant) for aggregate recovery.

- Utility Trenching: Creating precise trenches for water, gas, or fiber-optic lines in urban areas.

Railway Projects - Tunnel Boring: Fragmenting rock in mountainous tunnels for rail passage.

- Subgrade Stabilization: Compacting soil and crushed rock beneath rail tracks to enhance load-bearing capacity.

- Bridge Demolition: Safe dismantling of railway bridges and viaducts with vibration-controlled operation.

5. Marine & Ship Repair

Hull Maintenance:

- Removing marine growth (biofouling), rust, and paint from ship hulls (≤5 mm thickness). - Descaling steel surfaces before repainting or corrosion protection. - Port Infrastructure: - Ice breaking in Arctic ports to facilitate vessel movement. - Demolishing underwater concrete structures (e.g., old piers, breakwaters).

6. Specialized & Extreme Environments - Cold Regions: - Breaking frozen soil, permafrost, and ice (up to -40°C) for pipeline and foundation installation. - Ice sheet fragmentation for offshore platform construction. - Explosive Environments: - ATEX Zone 2-compliant models for debris clearance in hazardous areas (e.g., chemical plants, refineries). - Coastal Engineering: Compacting sediment to control erosion and stabilize seawalls.

7. Agriculture & Landscaping - Land Clearing: Removing boulders, tree stumps, and rocky terrain for agricultural or development projects. - Irrigation Trenching: Creating channels for pipelines using light-duty breakers (35–210 mm chisel diameter). - Livestock Facilities: Demolishing old barn foundations or concrete feedlots.

8. Urban Development & Utilities - Brownfield Redevelopment: Recycling concrete and steel from derelict sites for sustainable reuse. - Underground Utility Installation: Precision breaking for cable/pipe trenches in residential and commercial areas. - Heritage Projects: Gentle dismantling of historic structures with low-vibration, low-noise models.

Technical Advantages Highlighted: - Adjustable impact force for diverse material hardness (3,000–8,000 N). - High productivity rates (e.g., 8–12 tons/hour rock fragmentation). - Compliance with international standards (ISO, ASTM, ATEX). - Versatility across temperature ranges (-40°C to +50°C).

LXEM hydraulic breakers are engineered to optimize efficiency, safety, and sustainability across industrial, civil, and specialized applications.

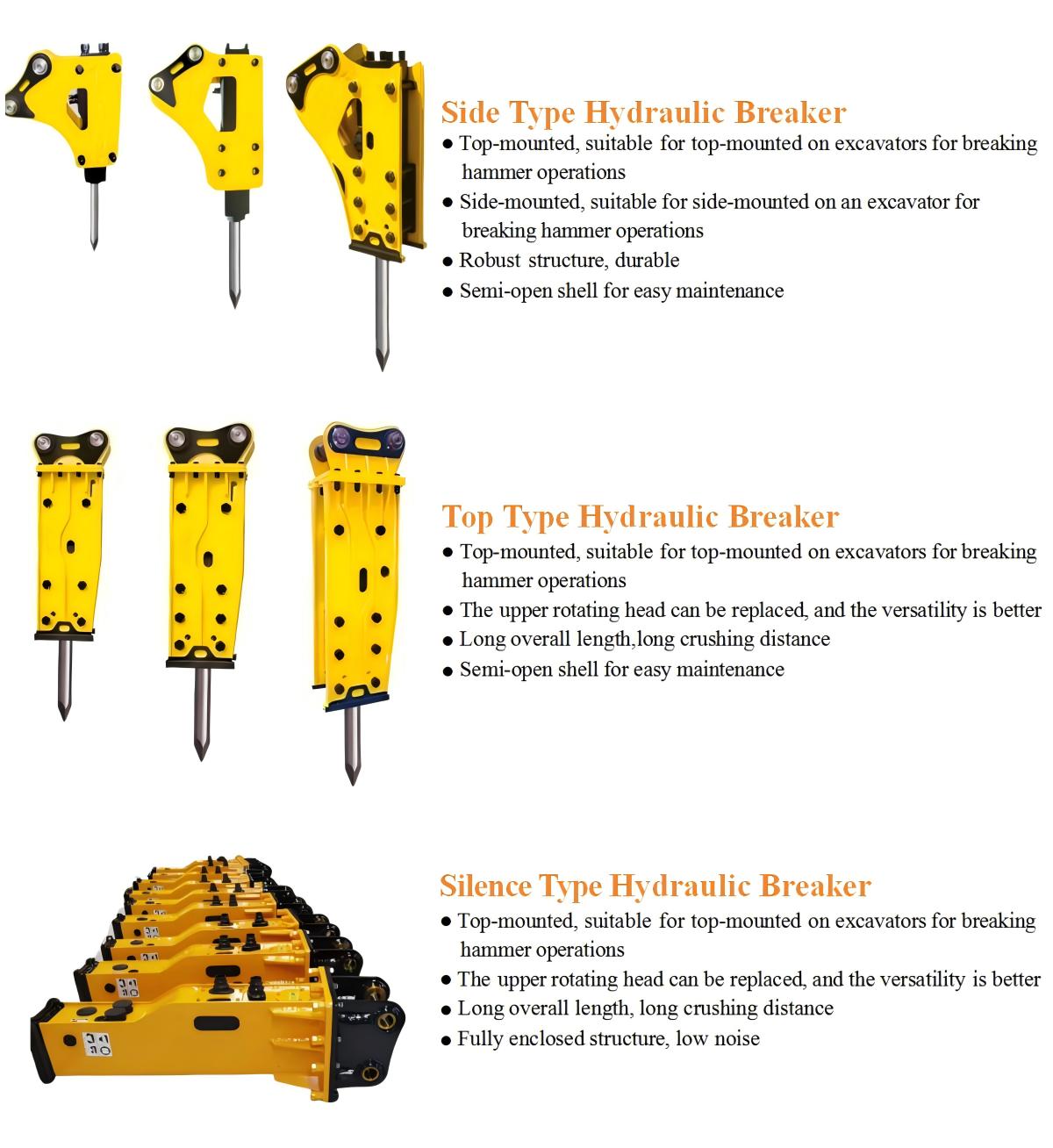

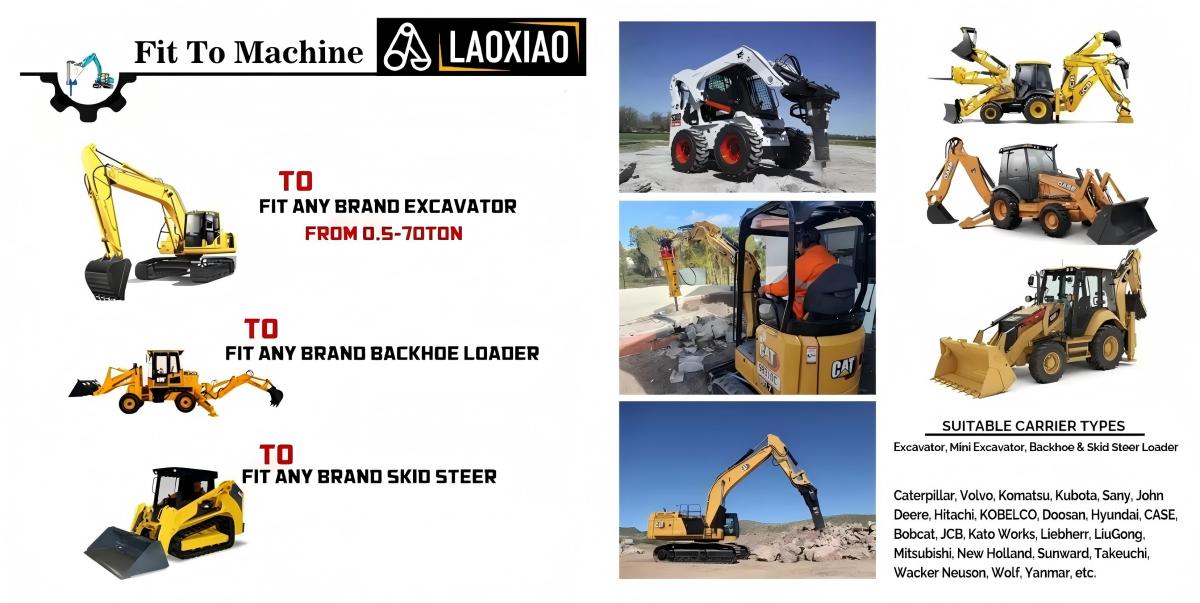

Key Features of the Hydraulic Breakers

Technical Specifications

The data is for reference only, and the specific product data is subject to the actual product.

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery