LXTS450 Top Separate Type Hydraulic Concrete Breaker Rock Hammer

Advantages of LXEM Hydraulic Breaker

• High-Efficiency Power System:Equipped with a high-performance engine for continuous, stable operation under heavy-duty workloads, ensuring peak productivity.

• Precision Control & Maneuverability:Integrated intelligent control system enables millimeter-level accuracy and agile steering, optimizing operational flexibility in complex tasks.

• Rugged Durability in Harsh Environments:Military-grade structural design withstands extreme conditions, including high temperatures, dust, moisture, and rough terrains.

• Low Vibration & Noise:Innovative damping technology reduces operational vibration and noise by 20% compared to alternative models, meeting strict environmental and workplace safety standards.

• Energy-Efficient Hydraulic Operation:Optimized hydraulic transmission system achieves 15% energy savings while maintaining high-power output, enhancing sustainability and cost-effectiveness.

• Multi-Material Versatility:Adapts seamlessly to concrete, steel, wood, and other materials, with quick-change attachments for efficient mode switching across applications.

• Low Maintenance Design:Key components feature maintenance-free or long-life designs, reducing annual maintenance costs by 30% and minimizing downtime for higher operational efficiency.

• Enhanced Job Site Safety:Comprehensive safety suite includes collision warning, overload protection, and emergency stop systems, ensuring compliance with rigorous safety regulations.

• Compact Design for Confined Spaces:Space-saving architecture (minimum width: [X] meters) allows easy navigation in narrow corridors, indoor environments, and other restricted areas.

• Long-Term Cost Efficiency:Whole-life cycle cost optimization delivers 25% lower total cost of ownership (TCO) over 5 years compared to traditional equipment, maximizing return on investment.

Applications of LXEM Hydraulic Breakers

Mining

• Mountainous area mining operations

• Open-pit/underground mining applications

• Grid screening & crushing processes

• Secondary crushing in mineral processing lines

Metallurgy

• Ladle maintenance & slag cleaning operations

• Industrial structure demolition (e.g., furnace bodies)

• Equipment foundation dismantling projects

Railway Engineering

• Mountainous terrain excavation for rail lines

• Tunnel boring & underground track construction

• Road/bridge demolition for rail realignment

• Subgrade stabilization & reinforcement works

Road Construction

• Highway maintenance & rehabilitation projects

• Cement pavement breaking & recycling

• Foundation excavation for road infrastructure

Municipal & Urban Utilities

• Concrete crushing in urban renewal projects

• Water/wastewater, power, and gas pipeline construction

• Old city reconstruction & infrastructure upgrading

Building Demolition

• Selective demolition of aged structures

• Reinforced concrete breaking & removal

• Interior/exterior dismantling in renovation projects

Special Applications

• Ice breaking in cold-region engineering

• Frozen soil excavation in permafrost areas

• Sand compaction & vibration-based ground treatment

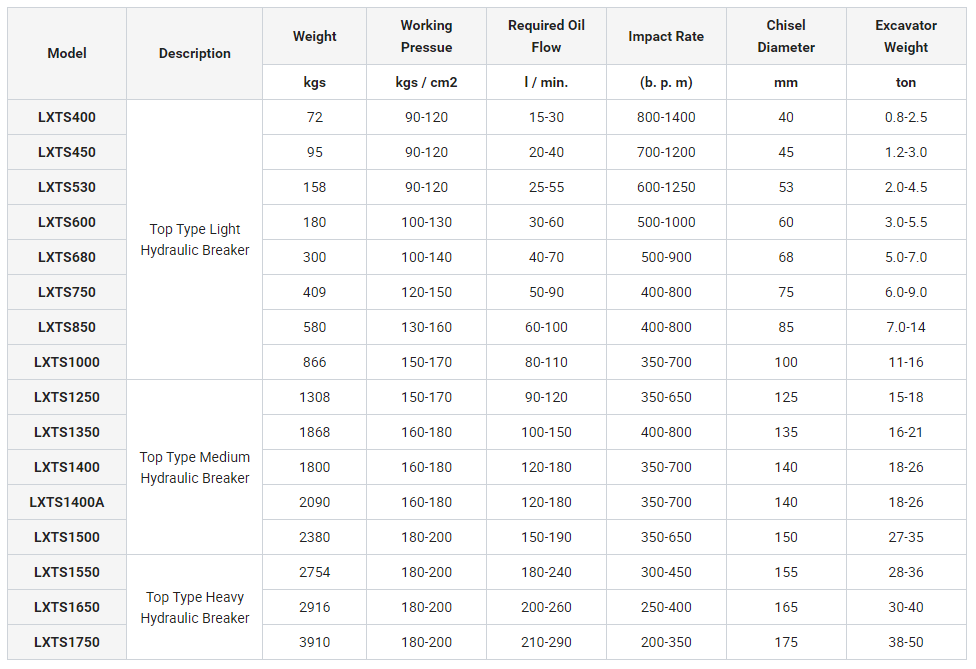

Technical Specifications

The data is for reference only, and the specific product data is subject to the actual product.

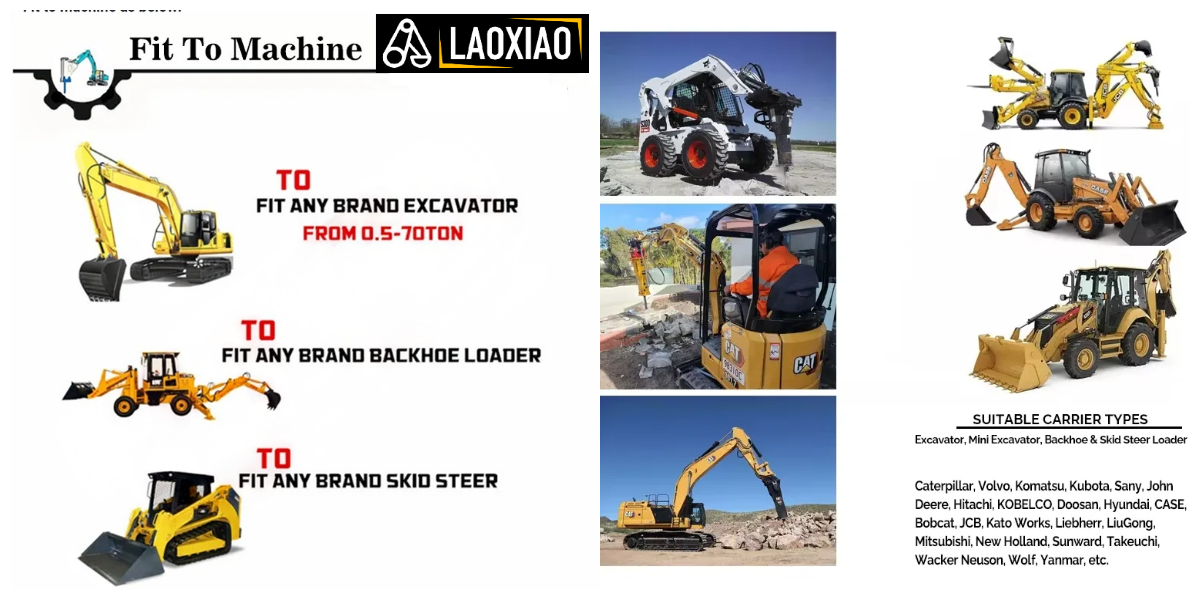

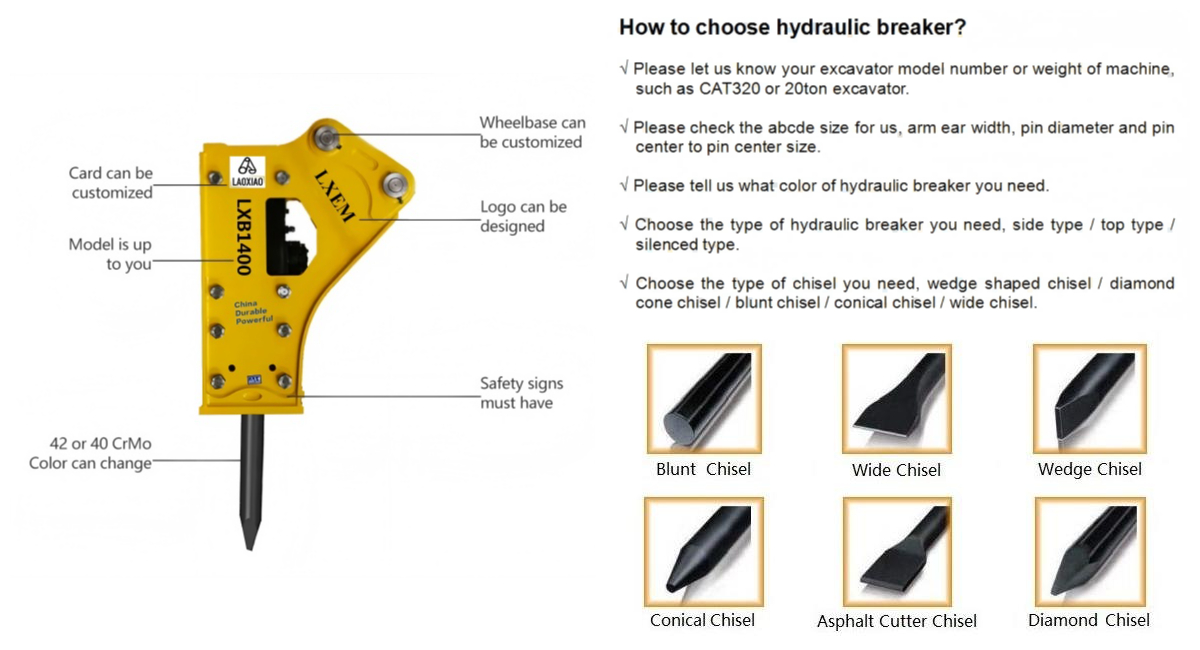

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery