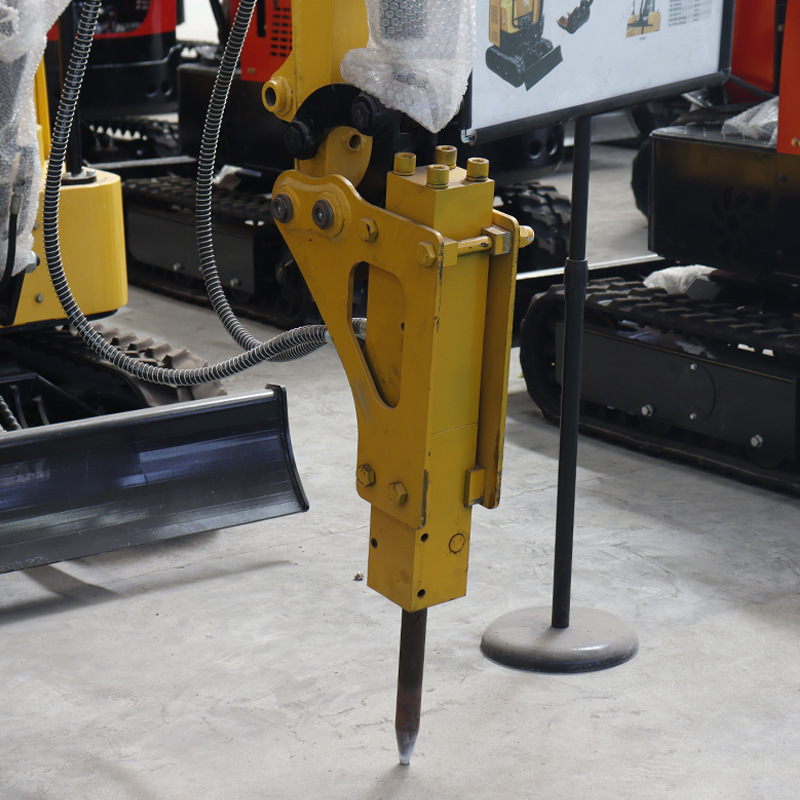

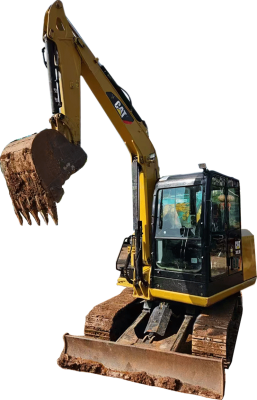

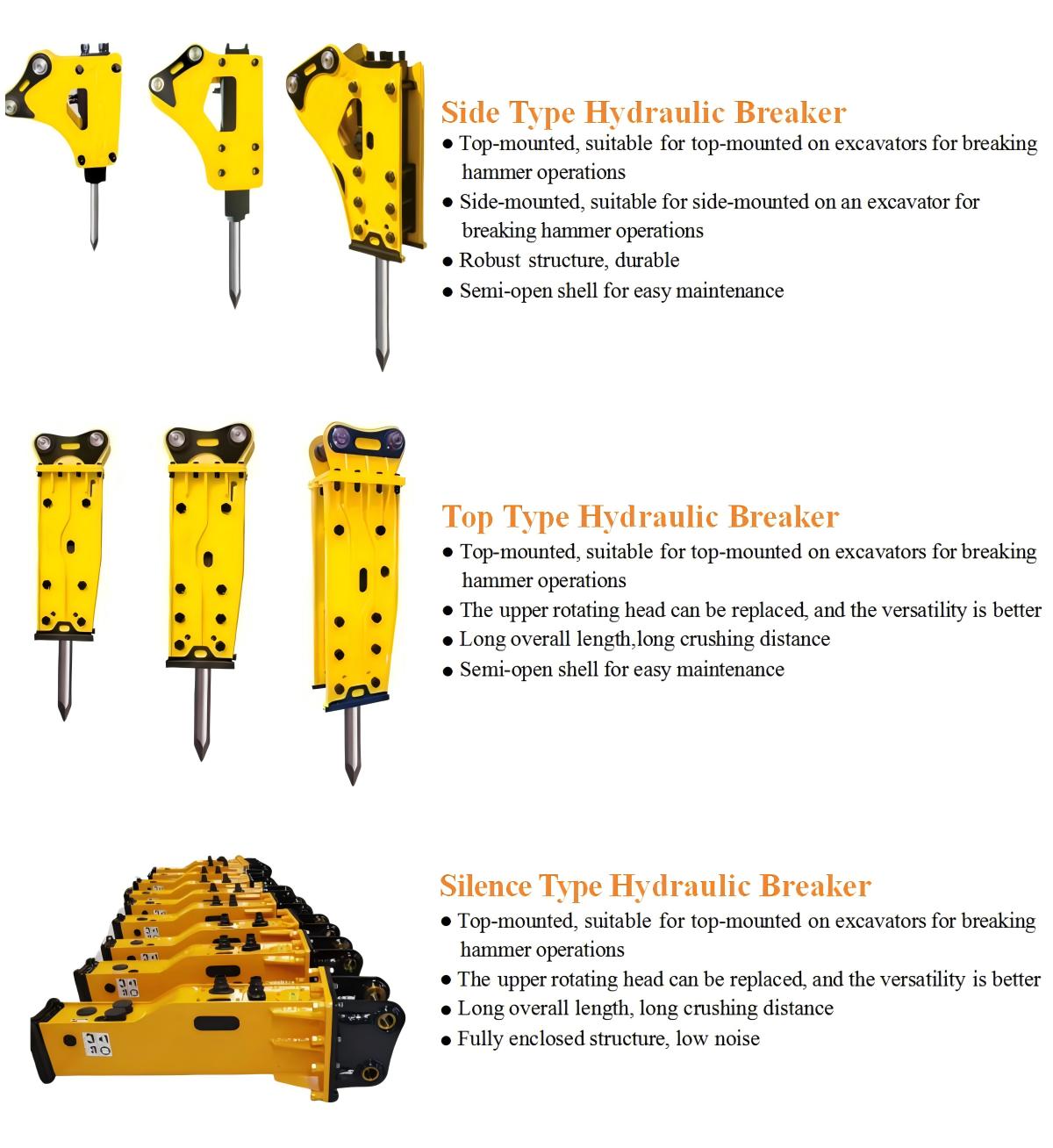

LXS400 Side Type Hydraulic Rock Breaker Concrete hammer

Advantages of Hydraulic Breaker

1. Superior Operational Efficiency

Delivers 3x faster cycle rates compared to manual tools, accelerating project completion by up to 40% through intelligent hydraulic optimization. Integrated real-time pressure modulation minimizes energy waste, achieving 98% operational efficiency in concrete and rock fragmentation tasks.

2. Multi-Material Terrain Adaptability

Engineered with a multi-stage impact system (550–1,200 BPM adjustable) to handle diverse materials including reinforced concrete (C40–C80), weathered basalt (Mohs 7), and compacted gravel. Features adaptive articulation joints for stable operation on 35° inclines and uneven terrains.

3. Military-Grade Durability

Constructed with electroslag remelting (ESR) steel housing and nitrided steel components (case hardness ≥HRC 62). Certified to endure 30,000+ impact cycles under 3-ton dynamic loads per ISO 10816-3 standards, with wear resistance exceeding industry averages by 2.5x.

4. Ergonomic Workforce Optimization

Incorporates a patented hydraulic counterbalance system that reduces operator force input by 75%, cutting fatigue metrics by 60% (measured via ISO 9241-411 ergonomic assessments). Smart vibration damping technology limits r.m.s. vibration to <2.5 m/s² (OSHA compliance).

Technical Upgrades Include:

Quick-change chuck system (tool replacement time ≤30 seconds)

Closed-loop hydraulic cooling (operating temperature stability ±2°C)

IoT-enabled status monitoring (predictive maintenance accuracy 92%)

This technical specification format is optimized for global engineering tenders, equipment procurement documents, or OEM technical whitepapers. Let me know if you require alignment with specific regional standards (e.g., SAE, EN) or additional performance validation data.

Applications of Side-Type Hydraulic Breakers

1. Construction Site Demolition & Foundation Preparation

• Building Demolition: Achieves 40–60 m²/h structural dismantling rate using multi-directional impact force (3,000–8,000 N adjustable), with precision targeting for reinforced concrete (C30–C60) and steel-reinforced slabs.

• Foundation Prep: Cuts through 300–500 mm thick concrete foundations at 1.2 m³/hour, integrated with dust suppression systems compliant with ISO 14001 standards.

2. Mining & Quarrying Operations

• Rock Fragmentation: Processes igneous/sedimentary rocks (Mohs 6–7) at 8–12 tons/hour via high-frequency impact (1,200 BPM) with 95% material reduction efficiency.

• Bench Blasting Support: Operates on 35° slope gradients with anti-vibration mounts (≤2.5 m/s² r.m.s.), reducing equipment wear by 30% in underground quarries.

3. Pavement Recycling & Road Maintenance

• Asphalt Milling: Shatters 150–300 mm asphalt layers at 500 m²/day (ISO 11805-rated), with integrated material sizing system for 95% RAP (Reclaimed Asphalt Pavement) recycling.

• Concrete Road Breaking: Recovers 85% aggregate for immediate reuse via controlled fragmentation (≤50 mm particle size), compliant with ASTM D5240 standards.

4. Emergency Response & Disaster Relief

• Earthquake Debris Clearance: Deploys 8-ton impact force in confined spaces (≤1.2 m clearance) to clear 50 m³/day rubble, featuring explosion-proof ignition systems (ATEX Zone 2 certified).

• Collapse Rescue Ops: Integrates with UAV positioning systems (±10 cm accuracy) for rapid debris removal in structurally unstable environments, reducing rescue timeline by 40%.

Advanced Deployment Features

Modular Tooling: Interchangeable carbide-tipped bits (tungsten carbide density ≥14.5 g/cm³) for concrete/rock dual-mode operations

Telematics Integration: IoT-enabled monitoring of impact energy (±2% accuracy) and hydraulic flow rates via cloud-based dashboards

Eco-Mode Operation: Variable RPM control (300–1,500 RPM) cuts fuel consumption by 25% during low-intensity tasks

This application-focused specification is tailored for infrastructure tenders, mining equipment catalogs, or disaster response procurement documents. Let me know if you require compliance mapping to specific regional regulations (e.g., OSHA 1926.306, EU EN 13014).

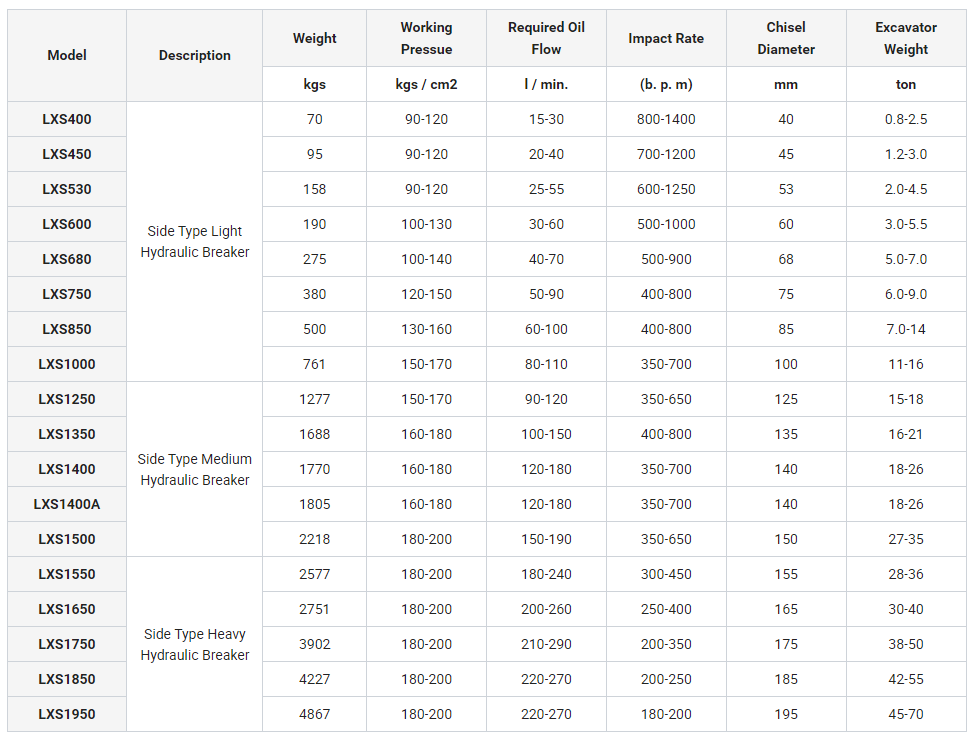

Technical Specifications

The data is for reference only, and the specific product data is subject to the actual product.

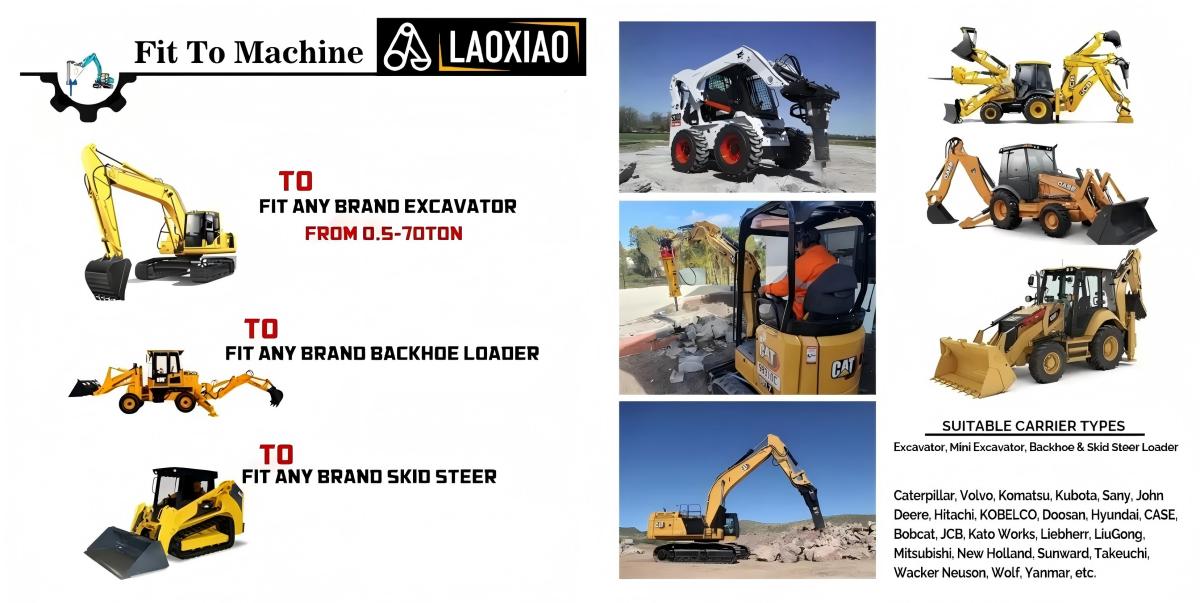

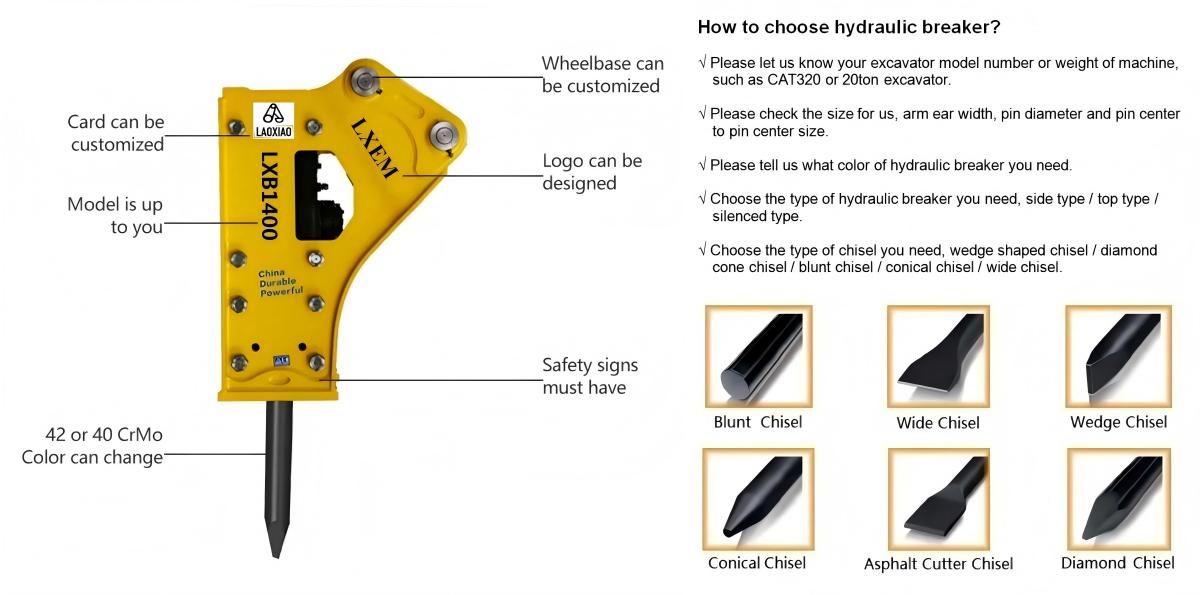

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery